|

|

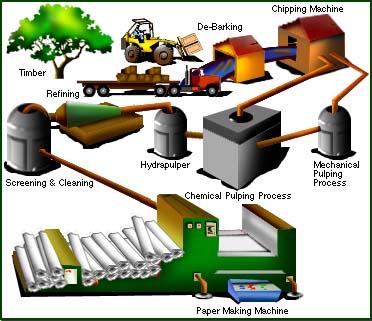

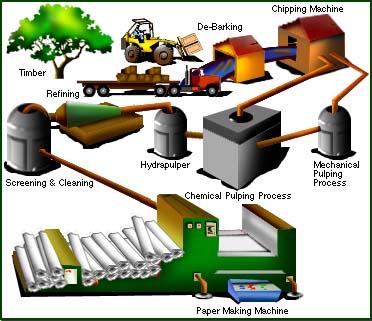

The craft of making paper basically is still the

same as it was when the whole notion of paper invention emerged in AD 105. The core

of paper making involves preparation of stock, formation of the paper web, drying

the sheet and finally application of coating and additives. Nowadays the only difference

is the technology and new innovations involved in the craft.

The paper making process

European paper makers

for instance, chose to craft it out of materials like cotton and linen fiber from rags. Initially, sorted and cleaned

rags are heated in an alkali solution. This is done in an open vat before the rags

are passed under steam pressure. Then the drained and seasoned rags are washed and

macerated to a pulp that will be bleached as to remove the unwanted traces of dyes

and residual darkening due to the cooking process.

Paper get its form

when a paper mold

is lifted out horizontally after being dipped into the vat of stock. This happens

when the fibers gets trapped against the screen of the mold. Hand made paper molds

consists of parallelly lengthen wires being laced together either by fine wires,

threads or even woven wire mesh.

Removed sheet from

the mold is pressed on the felts or woolen cloth. Post, a stack of paper sheets and

felts placed in a large wooden screw press will then be tightened by the workers

of the mill by pushing or pulling a long wooden lever. This leads to the production

of an average of 6-8 inches post out of a 2- foot. Once this task is completed, the

pressed sheets will be lifted and left to dry in relatively low number of groups known as "spurs". Far

away from soot and dust the "spurs" are dried at the highest level of the

mill.

Animal glue and

gelatin is used to make the paper less absorbent, and this is particularly important

for writing papers. Early 17th century witnessed the pioneer method for smoothing

paper using glossy stone and a water-powered hammer as a finishing touch.

Source of information: Museum

Tour: The Invention of Paper

|

|